I. Kukosha Kwekusarudza Cheni Necheni Kwazvo

Mumafekitori esimende, zvikwiriso zvemabucket zvakakosha pakutakura zvinhu zvinorema, zvinorema senge clinker, limestone, uye simende yakatwasuka.The round link cheni nemaketanitakura zvakanyanya kushushikana kwemagetsi, zvichiita kuti dhizaini yavo uye kugadzirwa kwemhando yekudzora kuve yakakosha pakubudirira kwekushanda. Heino chikonzero nei kusarudza zvinhu zvakanaka zvine basa uye kuti SCIC inogadzirisa sei izvi:

1. Kutakura-Kutakura Kukwanisa:Ngetani nemaketaniinofanirwa kumirisana nemitoro yakakura uye nekukatyamadzwa kubva mukuenderera mberi kwebucket kufamba. Zvinhu zvisina mwero zvinogona kukanganisa kutadza kamwe kamwe, zvichikonzera kuderera, njodzi dzekuchengetedza, uye kugadzirisa kunodhura. Kuomerera kweSCIC kumiyero yeDIN inova nechokwadi chekuti zvigadzirwa zvedu zvinozadzisa zvinodiwa zvesimba, senge rataurwa rekutyora simba re280–300 N/mm².

2. Pfeka Resistance: Iyo abrasive chimiro chesimende zvinhu zvinomhanyisa kupfeka pane zvinokwirisa. Maketani akaomeswa neketani (anosvika 800 HV) nemaketani (anosvika 600 HV) anopa nzvimbo yakasimba kuti irambe kuputika, uku ichichengetedza kuomarara kwepakati kudzivirira kutsemuka. SCIC's chaiyo carburizing process inowana yakakumbirwa 10% carburizing ukobvu uye 5-6% inoshanda kudzika kwekuomarara, kuve nechokwadi chekushanda kwenguva refu.

3. Kutevedza Mitemo: Kutevedza DIN 764, DIN 766, DIN 745, uye DIN 5699 inovimbisa kutingetani nemaketanisangana neindasitiri mabhenji ezviyero, zvinhu zvenyama, uye kuvimbika. Unyanzvi hweSCIC mukusangana nezviyero izvi hunova nechokwadi chekuenderana kwemhando yakarongedzwa kune rinorema-basa rekushandisa.

4. Kudzora Hunhu Hwekugadzira: Kudzora kwehutano hwakasimba hweSCIC-kubva pakusarudza zvinhu kusvika pakuongorora kwekupedzisira-inoderedza kuremara uye inova nechokwadi chekururama kwedimensional, kuoma, uye simba. Kugona uku kunoderedza mukana wekukundikana pasi pemamiriro akaomarara emafekitari esimende.

Kusarudza zvakanakangetani nemaketanikwakakosha pakubudirira uye kuchengetedzeka kwezvikwiriso zvebhakiti rako. KuSCIC, zvigadzirwa zvedu zvakagadzirirwa uye zvinogadzirwa kuti zvienderane nekuomesera kweDIN miyero, kuve nechokwadi kuti zvinokwanisa kushingirira mitoro inorema uye zvinokwesha zvinozivikanwa mumafekitori esimende. Nekusimba kwedu kwehutongi hwemhando, unogona kuvimba kuti maketani edu nemaketani zvichapa kuita kwakavimbika, kuderedza njodzi yekutadza kusingatarisirwe uye mari yekugadzirisa.

II. Kuenzanisa Kuoma uye Simba Panguva Yekugadzira

Kuwana kuomarara kwepamusoro kwakatsanangurwa nemutengi (800 HV yemacheni, 600 HV yemaketani), kukora kwecarburizing (10% yedhayamita yekubatanidza), kusimba kunoshanda (550 HV pa5-6% yedhayamita), uye simba rekupwanya (280–300 N/mm²) zvinoda kuenzanisa pakati pekuoma nesimba. Heano maitiro eSCIC anoita izvi kuburikidza nekusarudza zvinhu, kurapwa kwekupisa, uye carburizing:

Key Manufacturing Maitiro

1. Kusarudzwa kwezvinhu:Masimbi epamusoro-kabhoni kana alloy anosarudzwa nekuda kwekugona kwavo kupindura kune carburizing uye kudzima, zvichipa zvese kuoma kwepamusoro uye kuomarara kwepakati.

2. Carburizing:Carburizing inoparadzira kabhoni munzvimbo yesimbi kuti iwedzere kuoma. Nechetani yeketani ine 20 mm dhayamita;Carburizing Depth: 10% ye20 mm = 2 mm;Kubudirira Kuoma Kudzika: 5-6% ye20 mm = 1-1.2 mm pa 550 HV;Izvi zvinogadzira nzvimbo yakaoma, isingapfeki uku uchichengetedza ductile musimboti kuti utore mitoro ine simba.

3. Kurapa Kupisa:Kudzima: Mushure mekuviga, zvikamu zvinodzimwa kuvhara mukuoma kwepasi (800 HV yemaketani, 600 HV yemaketani);Kudzikamisa: Kudzora kushatirwa (semuenzaniso, pa200–250°C) kunogadzirisa zvinhu zvepakati, kuve nechokwadi chekuomarara uye simba rekupwanya rinodiwa re280–300 N/mm². Kunyanya-kushatirwa kunoderedza kuomarara, ukuwo kudzikisira kuchikonzera brittleness.

4. Bancing Act: Kuoma: Kuoma kwepamusoro kunopesana nekupfeka kubva kune zvinoputika;Simba: Core kuoma kunodzivirira brittle fractures pasi pemitoro inorema.SCIC inodzora kudzika kwecarburizing uye kudzikamisa paramita kudzivirira brittleness yakawandisa uchisangana nezvinodiwa nemutengi.

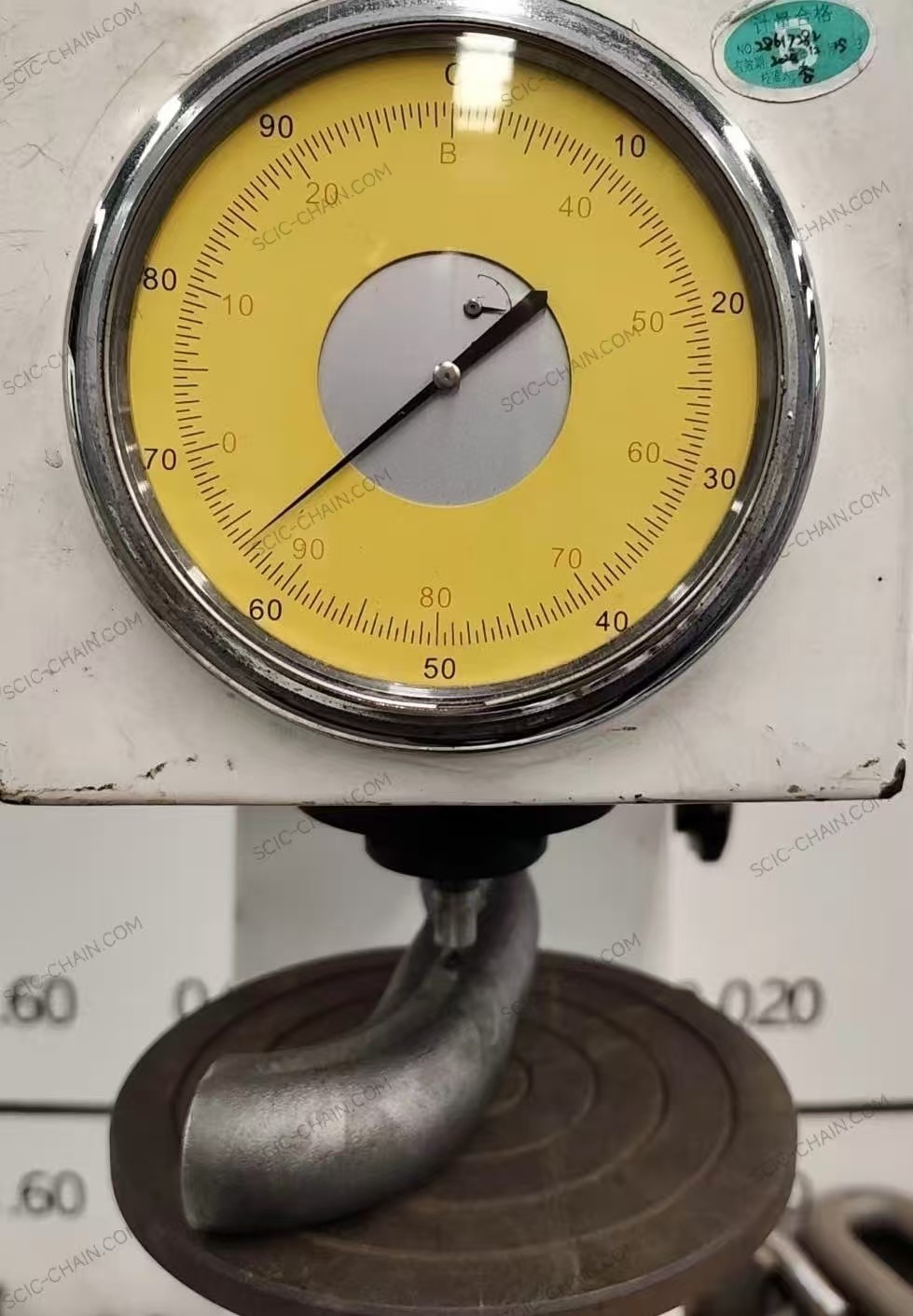

(macheni anongedzo ane high carburized surface kuoma)

(cheni zvinongedzo zvine yakakwira carburized pamusoro kuomarara, mushure mekutyora simba bvunzo)

Maitiro edu ekugadzira anodzorwa zvine hungwaru kuti awane chiyero chakakwana pakati pekuoma uye simba. Kuburikidza nekunyatso carburizing uye kurapwa kwekupisa, tinoona kuti yedungetani nemaketaniiva nenzvimbo yakaoma, isingapfeki uchichengeta musimboti wakaomarara wekubata mitoro ine simba mumabasa ako. Iyi chiyero yakakosha pakuwedzera hupenyu uye kuvimbika kwemidziyo.

III. Kuve nechokwadi cheHupenyu Kuburikidza Nekushanda uye Kuchengeta

Kunyangwe necheni dzemhando yepamusoro nemaketani, kushanda kwakakodzera uye kugadzirisa kwakakosha kuti uwedzere hupenyu hwesemende fekitori mabhaketi ekusimudza. SCIC inopa nhungamiro inotevera kune vatengi:

Maintenance Guidelines

1. Kugara Kuongorora:Checkngetani nemaketanizvezviratidzo zvekupfeka, sekurebesa (semuenzaniso, > 2–3% yehurefu hwepakutanga), deformation, kana kutsemuka kwepamusoro. Kukurumidza kuonekwa kunodzivirira kukundikana.

2. Kuzora:Isa mafuta ekuzora anopisa zvakanyanya, anorema kuti uderedze kukwenya nekupfeka. Mafuta 100-200 maawa ekushanda, zvichienderana nemamiriro ezvinhu.

3. Tension Monitoring:Chengetedza kwakaringana cheni tension kudzivirira kuderera zvakanyanya (kukonzera jerking) kana kuwedzeredza (kuwedzera kupfeka). Gadzirisa maererano neSCIC zvakatemwa.

4. Kutsiviwa Nenguva:Tsiva zvinhu zvakasakara kana kukuvara nekukurumidza kudzivirira kutadza kudonha. Semuenzaniso, cheni yakaremara inofanira kuchinjirwa kunze nekukasira.

5. Maitiro Akanyanya Kushanda:Shanda mukati memiganho yedhizaini (semuenzaniso, dzivirira kuremedza kupfuura iyo 280-300 N/mm² kutyora simba simba) kuderedza kushushikana.

Kuti uwedzere hupenyu hwengetani dzako nemaketani, tevera maitiro aya: gara uchiongorora kupfeka, chengetedza mafuta akakodzera, tarisa kushushikana kweketani, uye kutsiva zvinhu zvakakuvadzwa nekukurumidza. Nekutevedzera iyi nhungamiro uye kushanda mukati memiganho yedhizaini, unogona kuwedzera zvakanyanya kuvimbika uye kushanda zvakanaka kwemabhaketi ako ekusimudza.

Nyaya Yokudzidza: Real-World Impact

Mamiriro ezvinhu:

Fekitori yesimende yakatarisana nekazhinji denderedzwa rekubatanidza cheni tambo kutadza, nekudzikira kwemaawa gumi pamwedzi nekuda kwengetani dzine chete 600 HV kuomarara uye kudzika kwecarburizing kudzika. Izvi zvakakonzera kudhura kwekugadzirisa uye kurasikirwa kwekugadzirwa.

Solution:

Iyo fekitori yakagamuchira SCIC's kesi-yakaomeswa yakatenderedza yekubatanidza cheni:

- Paramita: 30mm dhayamita, 800 HV kuoma kwepasi, 3mm carburizing kudzika, 1.8mm kuoma kunoshanda pa550 HV, 290 N/mm² kutyora simba.

-Kugadzirisa: Bi-vhiki nevhiki kuongorora, mafuta ega ega maawa zana nemakumi mashanu, uye kugadziridzwa kwekunetsana.

(macheni anongedzo ane yakagadziridzwa carburizing kudzika kusvika 10% link dhayamita)

IV. Results

1. Nguva yekuzorora: Yakaderedzwa ne80% (kusvika kumaawa 2 / mwedzi).

2. Hupenyu: Maketani akapedza mwedzi 18 (vs. 6 mwedzi yapfuura).

3. Kuchengetedza Mutengo: Mari yekuchengeta yakaderera ne50% pagore.

Izvi zvinoratidza kuti SCIC's yepamusoro-mhando zvikamu uye nhungamiro yekugadzirisa zvinounza mabhenefiti anobatika.

V. Mhedziso

1. Kusarudza Izvo Zvikamu Zvakakodzera:SCIC's DIN-inoenderana cheni nemaketani, inotsigirwa nekugadzirwa kwepamusoro uye kutonga kwehutano, chengetedza kuchengeteka uye kubudirira mune simenti fekitari bhakiti elevators.

2. Kuenzanisa Kuoma uye Simba: Maitiro edu chaiwo ekugadzira anosangana nezvinodiwa nevatengi, kuendesa kupikisa kupfeka uye simba rekutakura.

3. Kuwedzera Hupenyu: Hutungamiri hwekugadzirisa hunoshanda hunovimbisa kuvimbika kwenguva refu.

Nekubatana neSCIC, vatengi vanowana mukana kune dzakagadzirwa nehunyanzvi cheni nemaketani, akarongedzerwa kune zvavanoda, uye anotsigirwa neakaratidza nzira dzekusimudzira mashandiro uye kuderedza mitengo.

Nguva yekutumira: Kubvumbi-21-2025